Understanding our Earth

We are a world-leading independent research organisation providing objective, expert geoscientific data, information and knowledge.

Latest news and events

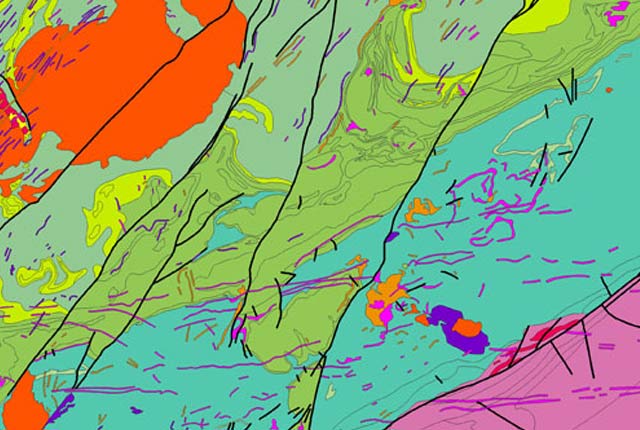

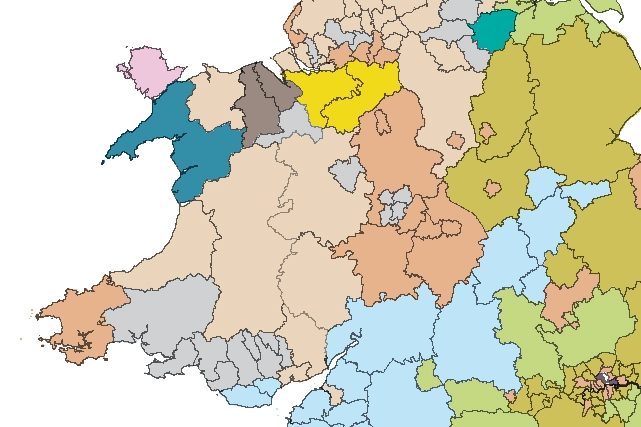

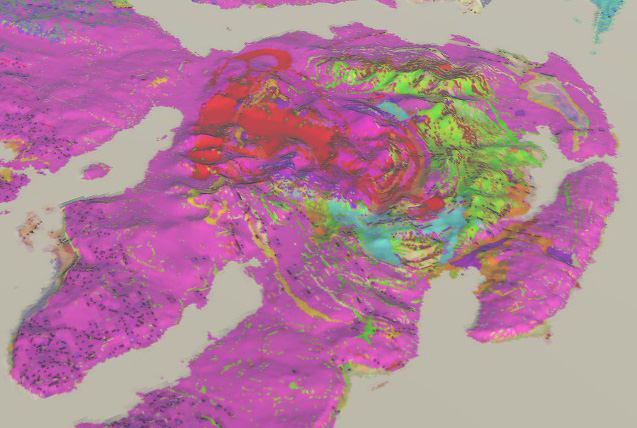

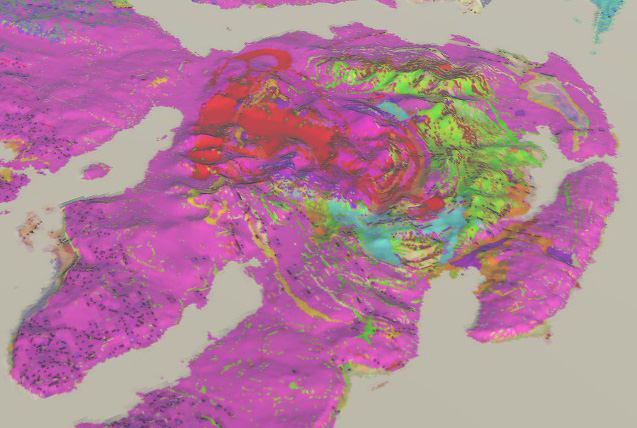

Map of BGS BritPits showing the distribution of worked mineral commodities across the country

18/02/2026

BGS’s data scientists have generated a summary map of the most commonly extracted mineral commodities by local authority area, demonstrating the diverse nature of British mineral resources.

MARC Conference 2025: highlighting the importance of conferences to PhD students

16/02/2026

BGS and University of Nottingham PhD student Paulina Baranowska shares her experience presenting her research on nuclear forensics at her first international conference.

Funding awarded to map the stocks and flows of technology metals in everyday electronic devices

12/02/2026

A new BGS project has been awarded Circular Electricals funding from Material Focus to investigate the use of technology metals in everyday electrical items.

New UK/Chile partnership prioritises sustainable practices around critical raw materials

09/02/2026

BGS and Chile’s Servicio Nacional de Geología y Minería have signed a bilateral scientific partnership to support research into critical raw materials and sustainable practices.

Extensive freshened water confirmed beneath the ocean floor off the coast of New England for the first time

09/02/2026

BGS is part of the international team that has discovered the first detailed evidence of long-suspected, hidden, freshwater aquifers.

Funding secured to help mitigate ground risk in UK construction sector

05/02/2026

The BGS Common Ground project has been awarded new funding to help unlock the value of ground investigation data.

After-school kids’ clubs

Event from 25/02/2026 to 25/03/2026

An after school club for junior geology enthusiasts

Can sandstones under the North Sea unlock the UK’s carbon storage potential?

02/02/2026

For the UK to reach its ambitious target of storing 170 million tonnes of carbon dioxide per year by 2050, it will need to look beyond the current well-studied geographical areas.

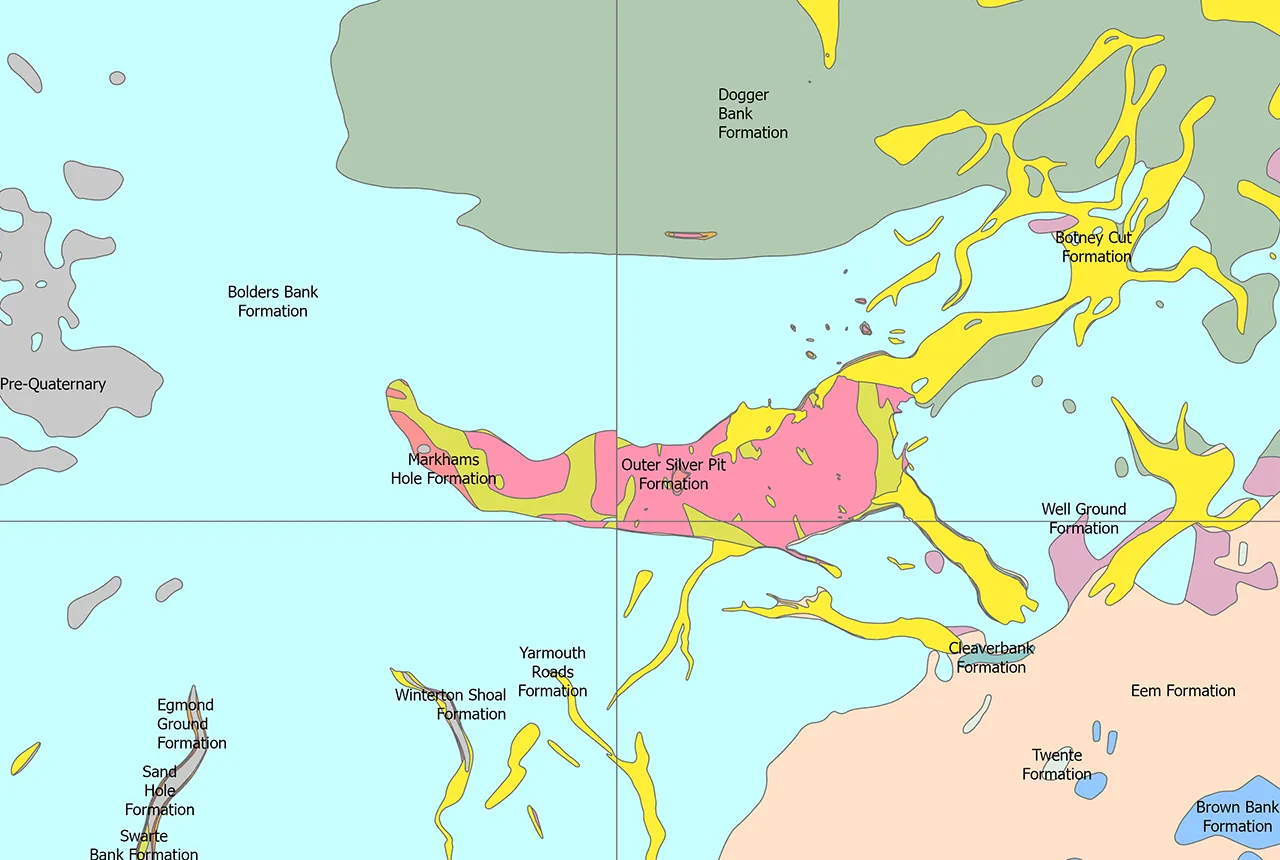

Quaternary UK offshore data digitised for the first time

21/01/2026

The offshore wind industry will be boosted by the digitisation of a dataset showing the Quaternary geology at the seabed and the UK’s shallow subsurface.

Suite of ten new soil reference materials released

02/01/2026

BGS has a longstanding track record of producing high-quality reference materials and has released ten new soil reference materials.

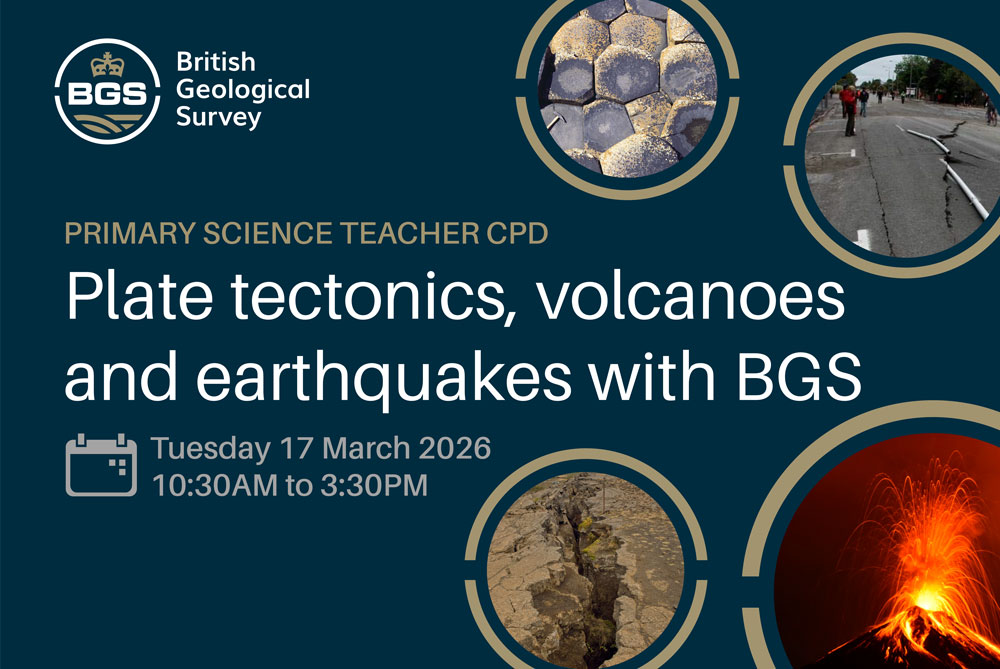

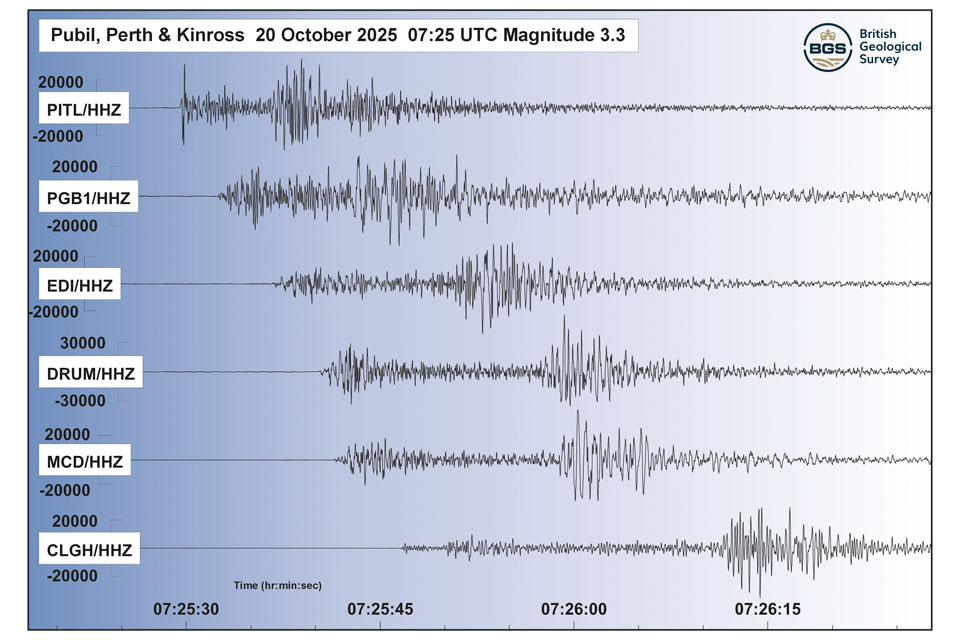

Perth and Kinross tops the UK’s earthquake activity charts for 2025

29/12/2025

Seismologists at BGS have published data on the number of seismic events over the past 12 months with over 300 earthquakes recorded.

Our core challenge areas

Decarbonisation and resource management

Decarbonisation of power production, heat, transport and industry is a major challenge and one that intrinsically involves geoscience.

Multi-hazards and resilience

We work with partners worldwide to enhance understanding of hazards, vulnerability, exposure and risk to ensure our science is useful, usable and used.

International geoscience

BGS is active across the globe delivering institutional strengthening programmes and applied research projects across a wide variety of sectors.

National geoscience

The National Geoscience programme is a forward-looking investment in UK geology that provides relevant, coherent and enriched geoscience knowledge for our stakeholders.

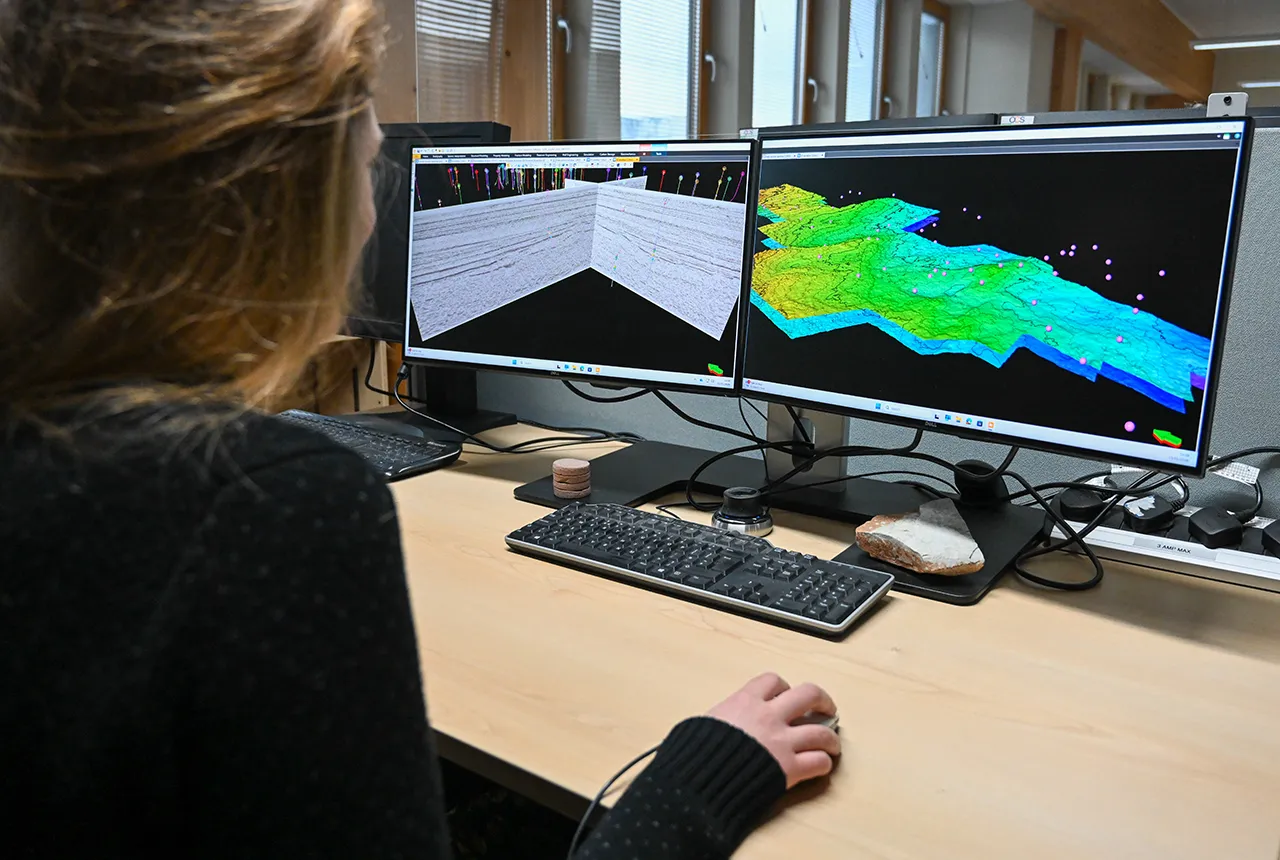

Digital geoscience

The BGS is a data-rich organisation. Our data science and data infrastructure are fundamental to our future research and underpin our strategic challenges.

Map viewers

Data published through map viewers allowing you to reveal more about the ground beneath your feet.

Technologies

Applications, software and online services created by the BGS and our collaborators.

Information hub

Data collections, publications, scanned records and other data gathered by BGS and provided by external organisations.

OpenGeoscience

Accessing maps and downloading data, scans, photos and other information via BGS’s free OpenGeoscience service.

Digital geoscience

The BGS is a data-rich organisation. Our data science and data infrastructure are fundamental to our future research and underpin our strategic challenges.

Digital data licensing and resellers

Providing a wide range of licences for the use and utilisation of our information products by for those interested in an information product and the Open Government Licence is not applicable.

National Geoscience Data Centre

Collecting and preserving geoscientific data, making it available to a wide range of users and communities.

National Geological Repository

Hosting BGS’s collections of borehole cores, cuttings, samples, specimens, and related subsurface information from the UK landmass and continental shelf.

Discovering Geology

Discovering Geology introduces a range of geoscience topics to school-age students and learners of all ages. Explore these pages to discover the fascinating processes and properties that shape our dynamic planet.

Rocks and minerals

Find out more about the differences between rocks and minerals and how they are formed.

Discovering Geology: climate change

What is the difference between weather and climate? what causes the Earth’s climate to change and what are the impacts? Find out more with our Discovery Geology climate change resources.

Earth hazards

The Earth beneath our feet is constantly shifting and moving, and violently with catastrophic and immediate results. Find out more about earth hazards.

Geological processes

Planet Earth is dynamic with a surface that is always changing. Find out about the processes that cause these changes.

Fossils and geological time

Take a look at the history of the Earth, from its formation over four and a half billion years ago to present times.

About BGS

As the national geological survey, we are the UK’s premier provider of objective and authoritative scientific data, information and knowledge to help society understand our Earth.

Our data and services

The BGS offers a range of services and information for businesses, home-owners, policymakers and the general public.

Working with us

BGS is committed to being an employer of choice and strives to embrace a culture of inclusivity and flexibility.

Offices and locations

Find out more about our offices and facilities located across the UK.

Contact us

Find out more about the BGS and the services we offer through our enquiries and customer services team.