Understanding our Earth

We are a world-leading independent research organisation providing objective, expert geoscientific data, information and knowledge.

Latest news and events

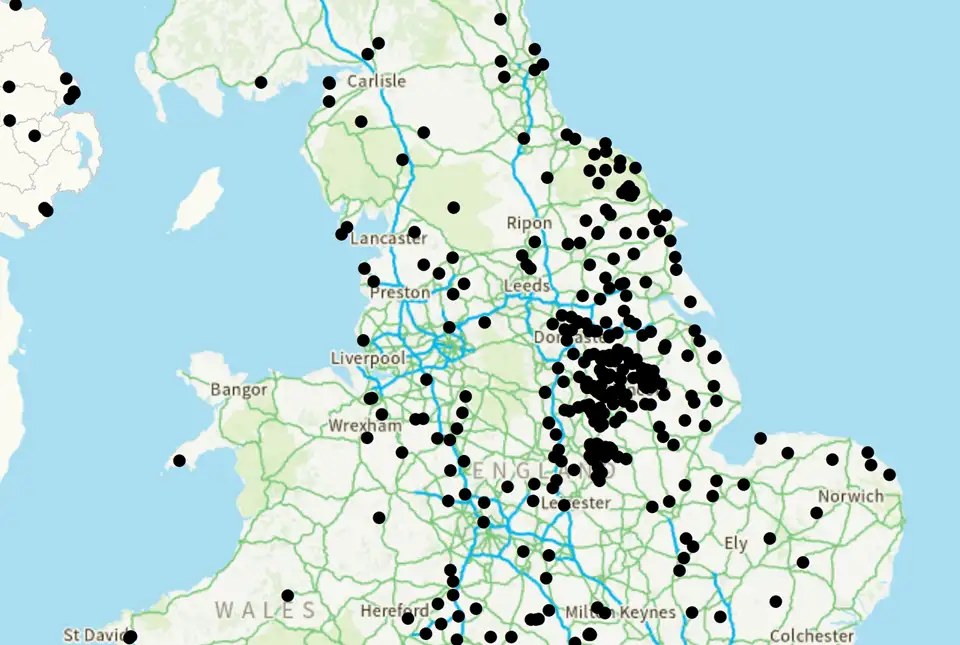

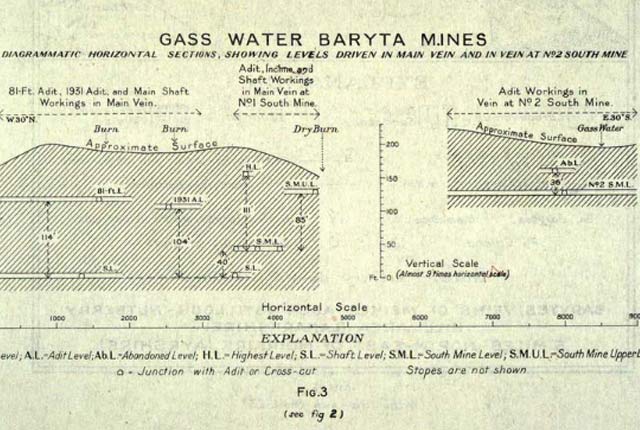

UK legacy geothermal catalogue released in digital format for the first time

18/04/2024

BGS has released the first digital version of the UK legacy geothermal catalogue of subsurface temperature measurements, rock thermal conductivity measurements and heat flow calculations.

New research supports conservation of fallow deer across Europe

16/04/2024

New research has combined zooarchaeology and ancient and modern biomolecular datasets to reveal new understandings into the history and projections of fallow deer.

BGS signs memorandum of understanding with Serviço Geológico do Brasil

10/04/2024

The partnership will advance the two organisations’ shared interests in mineral research and geoscience to help benefit society.

World Mineral Production 2018 to 2022 is now available

09/04/2024

The latest edition of World Mineral Production has been released.

New underground observatory open for research

09/04/2024

Construction has been completed on the Cheshire Observatory and the facility is now open for research activities.

2024 Mine Water Energy Symposium

Event from 24/04/2024 to 26/04/2024

Now in its fourth year, the 2024 Mine Water Energy Symposium will be held in person for the first time in April 2024, with online streaming functionality.

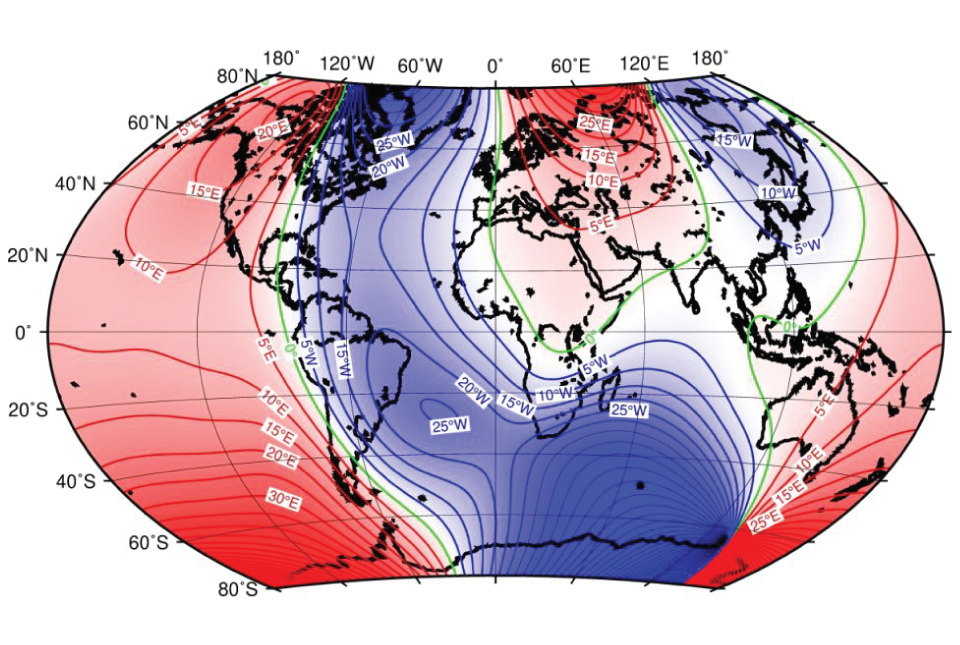

BGS leads update to maps of the Earth’s magnetic field

04/04/2024

The International Geomagnetic Reference Field, used for navigation on mobile phones and in space, is updated every five years.

UK bidding to host the International Geological Congress 2028

18/03/2024

BGS has partnered with the Geological Society of London and the Scottish Geology Trust to develop a bid to host the 38th International Geological Congress in Glasgow in 2028.

BGS to lead a new research project on microplastic occurrence in springs

06/03/2024

BGS has been awarded a two-year research project to undertake the first assessment of microplastic occurrence in springs in the UK.

Local MP helps BGS launch a ‘living laboratory’

05/03/2024

BGS is implementing a low-carbon heating system to help meet its net zero targets and provide data to the public.

Scientists produce first record of environmental data off coast of Hawai’i

01/03/2024

An international team of researchers, including BGS geoscientists, have succeeded in acquiring a continuous record of environmental data using fossilised coral from Hawai’i.

BGS Open Day 2024

Event on 08/06/2024

Join us on 8 June 2024 to explore volcanoes and earthquakes, soils and aquifers, the sea, the sky and everything in between!

Our core challenge areas

Decarbonisation and resource management

Decarbonisation of power production, heat, transport and industry is a major challenge and one that intrinsically involves geoscience.

Environmental change, adaptation and resilience

We are undertaking research aimed at reducing vulnerability, protecting resources and building resilience in response to substantial environmental changes.

Multi-hazards and resilience

We work with partners worldwide to enhance understanding of hazards, vulnerability, exposure and risk to ensure our science is useful, usable and used.

International geoscience

The BGS is active across the globe delivering institutional strengthening programmes and applied research projects across a wide variety of sectors.

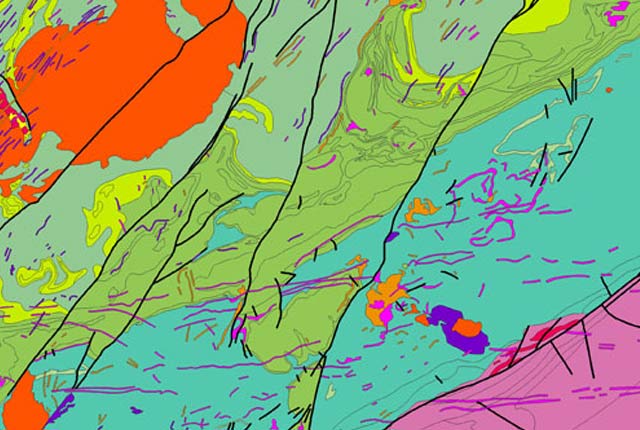

National geoscience

The National Geoscience programme is a forward-looking investment in UK geology that provides relevant, coherent and enriched geoscience knowledge for our stakeholders.

Digital geoscience

The BGS is a data-rich organisation. Our data science and data infrastructure are fundamental to our future research and underpin our strategic challenges.

Map viewers

Data published through map viewers allowing you to reveal more about the ground beneath your feet.

Technologies

Applications, software and online services created by the BGS and our collaborators.

Information hub

Data collections, publications, scanned records and other data gathered by BGS and provided by external organisations.

OpenGeoscience

OpenGeoscience is a free service where you can view maps, download data, scans, photos and other information.

Digital geoscience

The BGS is a data-rich organisation. Our data science and data infrastructure are fundamental to our future research and underpin our strategic challenges.

Digital data licensing and resellers

If you are interested in an information product and the Open Government Licence is not applicable, we encourage the use and exploitation of our information products by providing a wide range of licences.

National Geoscience Data Centre

The National Geoscience Data Centre collects and preserves geoscientific data, making it available to a wide range of users and communities.

National Geological Repository

The National Geological Repository holds our collections of borehole cores, cuttings, samples, specimens, and related subsurface information from the UK landmass and continental shelf.

Discovering Geology

Discovering Geology introduces a range of geoscience topics to school-age students and learners of all ages. Explore these pages to discover the fascinating processes and properties that shape our dynamic planet.

Rocks and minerals

Find out more about the differences between rocks and minerals and how they are formed.

Discovering Geology: climate change

What is the difference between weather and climate? what causes the Earth’s climate to change and what are the impacts? Find out more with our Discovery Geology climate change resources.

Earth hazards

The Earth beneath our feet is constantly shifting and moving, and violently with catastrophic and immediate results. Find out more about earth hazards.

Geological processes

Planet Earth is dynamic with a surface that is always changing. Find out about the processes that cause these changes.

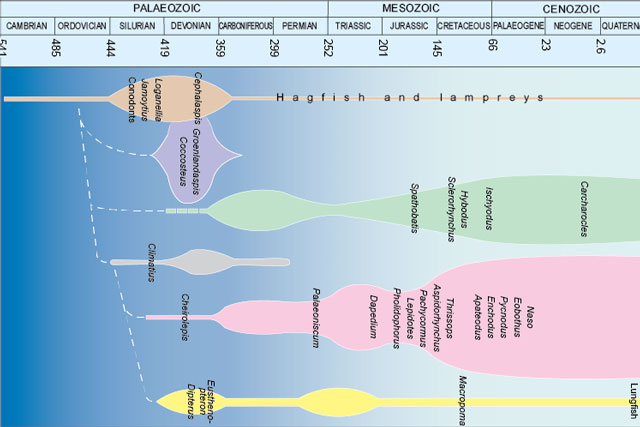

Fossils and geological time

Take a look at the history of the Earth, from its formation over four and a half billion years ago to present times.

About BGS

As the national geological survey, we are the UK’s premier provider of objective and authoritative scientific data, information and knowledge to help society understand our Earth.

Our data and services

The BGS offers a range of services and information for businesses, home-owners, policymakers and the general public.

Working with us

BGS is committed to being an employer of choice and strives to embrace a culture of inclusivity and flexibility.

Offices and locations

Find out more about our offices and facilities located across the UK.

Contact us

Find out more about the BGS and the services we offer through our enquiries and customer services team.